| Availability: | |

|---|---|

| Quantity: | |

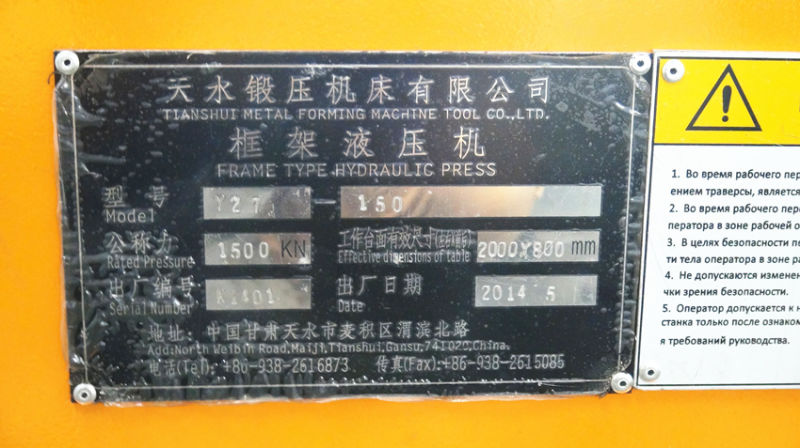

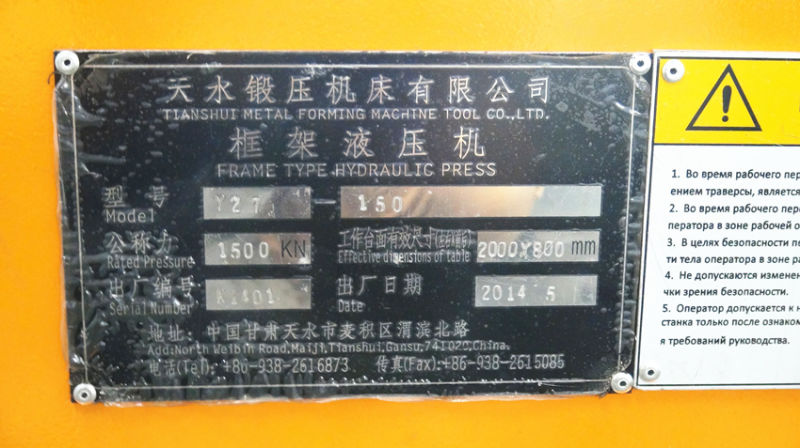

The Y27-150 is a high-performance 150t frame type hydraulic press equipped with a precision-engineered hydraulic cushion, specifically designed to meet the demands of precision metal forming applications in modern manufacturing. This robust machine integrates a stable three-column structure with an advanced PLC control system, which enables seamless transitions between manual, semi-automatic, and fully automatic operation modes to adapt to diverse production needs. The hydraulic cushion is a key feature that enhances versatility by providing adjustable counterpressure during critical processes such as deep drawing or stamping, ensuring consistent part quality across a wide range of materials including high-strength steel, aluminum alloys, and copper.

Constructed with a heavy-duty welded steel frame tempering treatment to eliminate internal stress, the Y27-150 delivers exceptional rigidity and structural stability even under continuous heavy loads. Its interchangeable tooling system supports quick mold changes, reducing downtime between production runs. Equipped with a user-friendly touchscreen interface, operators can easily monitor real-time parameters such as pressure, stroke position, and cushion force, enabling precise control over every forming stage. Safety features including emergency stop buttons, overload protection, and a protective light curtain ensure compliance with international safety standards, making it a reliable choice for high-volume production environments.

Nominal Force: 1500kN (150t)

Hydraulic Cushion Force: 400kN (adjustable within 10-100% range)

Slider Stroke: 600mm (with multi-stage stroke setting function)

Maximum Open Height: 900mm

Worktable Size: 690mm (L) × 630mm (W) (with T-slot spacing of 100mm)

Liquid Pressure: 25MPa

Stroke Speed:

Rapid Approach: 80mm/s

Working Speed: 10mm/s (continuously adjustable)

Return Speed: 70mm/s

Motor Power: 11kW (variable frequency drive for energy efficiency)

Machine Dimensions: 2200mm × 1800mm × 3100mm

Net Weight: 12000kg

CE Certification: Compliant with EU safety standards

Automotive Manufacturing: Ideal for forming car body panels with complex curves, chassis components requiring high structural strength, and exhaust system parts resistant to high temperatures. It excels in producing precision parts for both passenger vehicles and commercial trucks.

Aerospace: Used in producing aircraft structural parts such as wing ribs and fuselage components, as well as turbine components requiring strict dimensional tolerances. The adjustable pressure settings ensure compatibility with lightweight aerospace alloys.

Appliance Industry: Forms refrigerator shells with smooth surfaces, washing machine drums with corrosion-resistant finishes, and oven parts that can withstand high-temperature environments. Its precision control reduces material waste in mass production.

Metal Fabrication: Supports deep drawing of cylindrical and rectangular parts, embossing of decorative patterns on metal surfaces, and bending of steel, aluminum, and stainless steel sheets up to 8mm thickness. It is widely used in custom metal processing workshops.

Q: Can the Y27-150 handle non-ferrous metals?

A: Yes, it efficiently processes aluminum, copper, brass, and other non-ferrous materials. The machine’s adjustable pressure (50-1500kN) and speed settings (5-10mm/s working speed) allow operators to optimize parameters for different material properties, ensuring smooth forming without cracking or deformation.

Q: What is the typical maintenance interval?

A: Routine maintenance checks are recommended every 500 operating hours. This includes hydraulic fluid replacement (using ISO VG46 anti-wear hydraulic oil), filter cleaning, sensor calibration, and lubrication of guide rails. Annual comprehensive maintenance is advised to inspect seals, hydraulic hoses, and structural components for wear.

Q: Does the machine support custom tooling?

A: Yes, the Y27-150 is fully compatible with ISO-standard tooling (DIN 1628) for universal applications. Our in-house engineering team can also design bespoke tooling solutions based on specific part drawings, including custom die sets and forming molds with quick-change mechanisms.

Q: How long does installation take?

A: On-site installation and commissioning are typically completed within 3-5 business days post-delivery. This includes machine positioning, electrical connection, hydraulic system testing, and operator training covering basic operation, parameter setup, and safety protocols. We also provide online technical support for any post-installation issues.

|  |

|  |

|  |

The Y27-150 is a high-performance 150t frame type hydraulic press equipped with a precision-engineered hydraulic cushion, specifically designed to meet the demands of precision metal forming applications in modern manufacturing. This robust machine integrates a stable three-column structure with an advanced PLC control system, which enables seamless transitions between manual, semi-automatic, and fully automatic operation modes to adapt to diverse production needs. The hydraulic cushion is a key feature that enhances versatility by providing adjustable counterpressure during critical processes such as deep drawing or stamping, ensuring consistent part quality across a wide range of materials including high-strength steel, aluminum alloys, and copper.

Constructed with a heavy-duty welded steel frame tempering treatment to eliminate internal stress, the Y27-150 delivers exceptional rigidity and structural stability even under continuous heavy loads. Its interchangeable tooling system supports quick mold changes, reducing downtime between production runs. Equipped with a user-friendly touchscreen interface, operators can easily monitor real-time parameters such as pressure, stroke position, and cushion force, enabling precise control over every forming stage. Safety features including emergency stop buttons, overload protection, and a protective light curtain ensure compliance with international safety standards, making it a reliable choice for high-volume production environments.

Nominal Force: 1500kN (150t)

Hydraulic Cushion Force: 400kN (adjustable within 10-100% range)

Slider Stroke: 600mm (with multi-stage stroke setting function)

Maximum Open Height: 900mm

Worktable Size: 690mm (L) × 630mm (W) (with T-slot spacing of 100mm)

Liquid Pressure: 25MPa

Stroke Speed:

Rapid Approach: 80mm/s

Working Speed: 10mm/s (continuously adjustable)

Return Speed: 70mm/s

Motor Power: 11kW (variable frequency drive for energy efficiency)

Machine Dimensions: 2200mm × 1800mm × 3100mm

Net Weight: 12000kg

CE Certification: Compliant with EU safety standards

Automotive Manufacturing: Ideal for forming car body panels with complex curves, chassis components requiring high structural strength, and exhaust system parts resistant to high temperatures. It excels in producing precision parts for both passenger vehicles and commercial trucks.

Aerospace: Used in producing aircraft structural parts such as wing ribs and fuselage components, as well as turbine components requiring strict dimensional tolerances. The adjustable pressure settings ensure compatibility with lightweight aerospace alloys.

Appliance Industry: Forms refrigerator shells with smooth surfaces, washing machine drums with corrosion-resistant finishes, and oven parts that can withstand high-temperature environments. Its precision control reduces material waste in mass production.

Metal Fabrication: Supports deep drawing of cylindrical and rectangular parts, embossing of decorative patterns on metal surfaces, and bending of steel, aluminum, and stainless steel sheets up to 8mm thickness. It is widely used in custom metal processing workshops.

Q: Can the Y27-150 handle non-ferrous metals?

A: Yes, it efficiently processes aluminum, copper, brass, and other non-ferrous materials. The machine’s adjustable pressure (50-1500kN) and speed settings (5-10mm/s working speed) allow operators to optimize parameters for different material properties, ensuring smooth forming without cracking or deformation.

Q: What is the typical maintenance interval?

A: Routine maintenance checks are recommended every 500 operating hours. This includes hydraulic fluid replacement (using ISO VG46 anti-wear hydraulic oil), filter cleaning, sensor calibration, and lubrication of guide rails. Annual comprehensive maintenance is advised to inspect seals, hydraulic hoses, and structural components for wear.

Q: Does the machine support custom tooling?

A: Yes, the Y27-150 is fully compatible with ISO-standard tooling (DIN 1628) for universal applications. Our in-house engineering team can also design bespoke tooling solutions based on specific part drawings, including custom die sets and forming molds with quick-change mechanisms.

Q: How long does installation take?

A: On-site installation and commissioning are typically completed within 3-5 business days post-delivery. This includes machine positioning, electrical connection, hydraulic system testing, and operator training covering basic operation, parameter setup, and safety protocols. We also provide online technical support for any post-installation issues.

|  |

|  |

|  |

| No. | Name | Unit | Value | |

| 1 | Nominal force | KN | 1500 | |

| 2 | Force of hydraulic cushion | KN | 400 | |

| 3 | Max.working pressure of hydraulic | Mpa | 25 | |

| 4 | Max.opening height | mm | 800 | |

| 5 | Max.stroke of slide block | mm | 600 | |

| 6 | Stroke of hydraulic cushion | mm | 300 | |

| 7 | Speed of slide block | Descent | mm/s | 100 |

| Pressing | mm/s | 5~10 | ||

| Return | mm/s | 65 | ||

| 8 | Table size | Left-Right | mm | 2000 |

| Front-Back | mm | 800 | ||

| 9 | Hydraulic cushion size | Left-Right | mm | 1000 |

| Front-Back | mm | 550 | ||

| 10 | Height from working table to floor | mm | 750 | |

| 11 | Total motor power | kw | 11 | |

| 12 | Height above floor | mm | 4400 | |

| 13 | Floor space of machine (Left-Right X Front-Back) | mm | 5600x2900 | |

| No. | Name | Unit | Value | |

| 1 | Nominal force | KN | 1500 | |

| 2 | Force of hydraulic cushion | KN | 400 | |

| 3 | Max.working pressure of hydraulic | Mpa | 25 | |

| 4 | Max.opening height | mm | 800 | |

| 5 | Max.stroke of slide block | mm | 600 | |

| 6 | Stroke of hydraulic cushion | mm | 300 | |

| 7 | Speed of slide block | Descent | mm/s | 100 |

| Pressing | mm/s | 5~10 | ||

| Return | mm/s | 65 | ||

| 8 | Table size | Left-Right | mm | 2000 |

| Front-Back | mm | 800 | ||

| 9 | Hydraulic cushion size | Left-Right | mm | 1000 |

| Front-Back | mm | 550 | ||

| 10 | Height from working table to floor | mm | 750 | |

| 11 | Total motor power | kw | 11 | |

| 12 | Height above floor | mm | 4400 | |

| 13 | Floor space of machine (Left-Right X Front-Back) | mm | 5600x2900 | |