Views: 0 Author: Site Editor Publish Time: 2025-10-23 Origin: Site

Presses are essential in industries for shaping, forming, and assembling various products. Hydraulic and pneumatic presses are two of the most common types. They generate force using different methods and serve distinct roles in manufacturing.

In this article, we will explore the differences between hydraulic and pneumatic presses. You'll learn about their unique capabilities, costs, and performance. This comparison will help you choose the right press for your needs.

A hydraulic press is a machine that uses the principles of hydraulics to generate force through pressurized fluid. According to Pascal’s Law, pressure applied to a confined fluid is transmitted equally in all directions, allowing for the multiplication of force. This press uses hydraulic oil or another type of fluid, which cannot be compressed, to transfer the force.

The key components of a hydraulic press include:

● Hydraulic Cylinder: Contains a piston that moves under pressure to apply force.

● Hydraulic Pump: Pressurizes the hydraulic fluid.

● Reservoir: Holds the hydraulic fluid.

● Control Valves: Regulate the fluid flow, pressure, and force.

Hydraulic presses can generate incredibly high forces, making them ideal for heavy-duty applications such as metal forming, deep drawing, and large-scale assembly tasks.

A pneumatic press, on the other hand, uses compressed air to generate force. Pneumatic presses operate by using pressurized gas, typically air, which moves a piston within a cylinder. The compressed air is directed into the cylinder through valves, pushing the piston to apply force.

The key components of a pneumatic press include:

● Compressor: Pressurizes the air.

● Reservoir: Stores the compressed air.

● Pneumatic Cylinder: Houses the piston that moves under air pressure.

● Valves: Control the flow of compressed air and the piston’s movement.

Pneumatic presses are best suited for tasks that require speed, precision, and moderate force, such as light assembly and stamping.

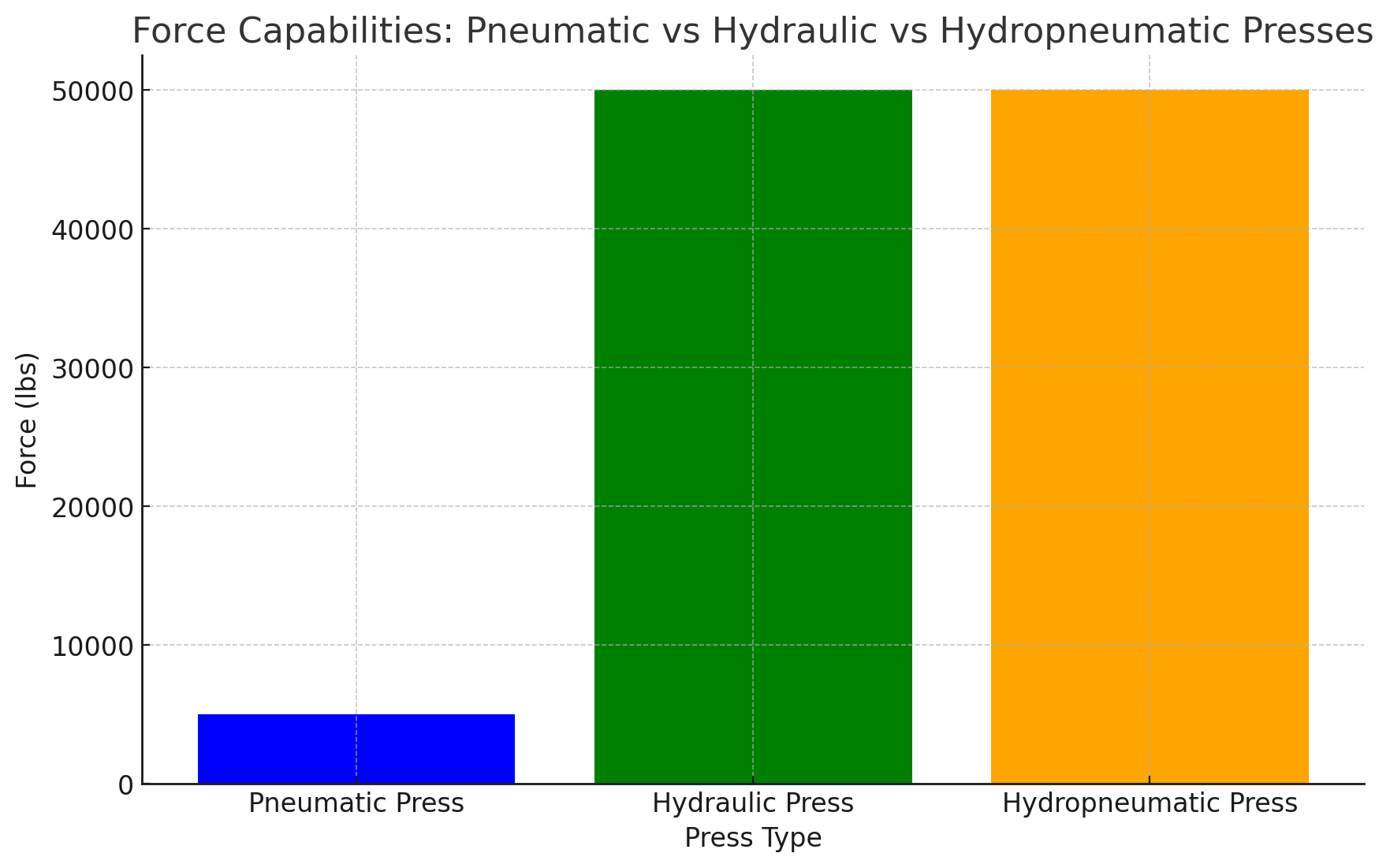

One of the most significant differences between hydraulic and pneumatic presses is their force capabilities. Hydraulic presses are capable of generating extremely high forces, often up to 50 tons or more, thanks to their ability to multiply force through hydraulic fluid. This makes them ideal for tasks that require sustained pressure over long periods, such as deep drawing, forging, and heavy-duty metal forming.

In contrast, pneumatic presses are typically limited to lower force outputs, usually ranging from 150 to 5,000 pounds of force. Pneumatic systems excel in high-speed tasks but lack the raw power of hydraulic presses. Therefore, pneumatic presses are more suitable for applications like light assembly, riveting, or punching, where force requirements are not as demanding.

When it comes to speed, pneumatic presses generally outperform hydraulic presses. Pneumatic systems are fast because air, being less viscous than hydraulic fluid, moves quickly through valves and cylinders. This allows pneumatic presses to achieve high cycle rates, making them ideal for high-volume production environments where quick turnaround times are essential.

Hydraulic presses, while slower, offer a more controlled and consistent force throughout the stroke. Due to the nature of fluid mechanics, hydraulic presses take more time to build and release pressure, resulting in slower cycle times. However, this slower operation can be an advantage when precision and sustained force are required for intricate operations.

Hydraulic presses are known for their precision and control. The incompressibility of hydraulic fluid allows for precise regulation of pressure, force, and speed, making hydraulic presses the go-to choice for tasks that require accurate, repeatable results, such as molding, deep drawing, and other intricate operations. Hydraulic presses can maintain full force at any point in the stroke, which is essential for operations that need consistent pressure, like forming high-strength materials.

Pneumatic presses, although capable of fast cycles, struggle to offer the same level of precision. The compressibility of air causes a variable force output, with the maximum force typically occurring only at the end of the stroke. While pneumatic presses offer excellent positional repeatability, their force control is less accurate compared to hydraulic presses.

Pneumatic presses are generally more affordable than hydraulic presses due to their simpler design and fewer components. The cost of a pneumatic press can range from a few thousand dollars for smaller, benchtop models to tens of thousands for larger, industrial versions. The simplicity of pneumatic presses also makes them easier and cheaper to manufacture.

On the other hand, hydraulic presses are more expensive to purchase, often due to their more complex systems and the need for high-pressure hydraulic pumps, motors, and reservoirs. The initial investment for a hydraulic press can be up to three to five times higher than a comparable pneumatic press, especially for models capable of generating high forces.

While pneumatic presses are cheaper to buy, they can incur higher operating costs over time. Compressed air is inherently inefficient, and maintaining a consistent supply of pressurized air can add to operating expenses. Furthermore, pneumatic systems may require more frequent maintenance due to the wear and tear of air cylinders and seals.

Hydraulic presses, while more expensive to maintain, tend to be more energy-efficient in the long run, especially for tasks that require sustained force. They do require regular maintenance, including monitoring fluid levels, replacing seals, and maintaining the hydraulic pump, but their durability and longer lifespans can make them a more cost-effective solution over time for heavy-duty operations.

Hydraulic presses are the ideal choice for heavy-duty tasks that require immense force and precision. They excel in industries such as:

● Automotive: Shaping and forming metal body parts, like car doors and panels.

● Aerospace: Producing high-strength components and deep drawing operations.

● Manufacturing: Molding, stamping, and forming materials like metals, plastics, and composites.

For tasks that involve tough materials or require constant pressure throughout the process, a hydraulic press is the best solution.

Pneumatic presses are best suited for light to moderate tasks that require speed and precision but not extreme force. Applications include:

● Assembly: Fast assembly of components such as rivets, nails, or connectors.

● Stamping: Light stamping of thin metals, plastics, and foils.

● Medical Devices: Ideal for cleanroom environments where contamination from oils is a concern.

Pneumatic presses are also a great choice for high-volume production environments where speed is the primary consideration.

While hydraulic presses offer immense power, they come with safety concerns that must be addressed. Hydraulic fluid is under high pressure, and a leak or burst hose can lead to dangerous conditions, such as fluid injection injuries. Additionally, hydraulic presses can generate substantial noise, which could be hazardous without proper hearing protection.

Pneumatic presses, although safer in some respects, still come with risks. High-pressure air can cause injuries, particularly if it escapes suddenly or is mishandled. Furthermore, pneumatic presses can generate significant noise during operation, especially during the exhaust phase, which requires attention to hearing protection.

A hydropneumatic press combines the speed of a pneumatic system with the force of a hydraulic one. It uses compressed air for the approach stroke and hydraulic fluid for the power stroke, giving it a balance of rapid movement and powerful force.

The main advantages of hydropneumatic presses include:

● Speed: Quick approach and retraction due to the pneumatic system.

● Force: Powerful force delivery during the work stroke thanks to hydraulic fluid.

● Efficiency: Reduced energy consumption compared to fully hydraulic systems.

● Cost-Effective: Generally cheaper than pure hydraulic presses with similar force capabilities.

In conclusion, the choice between a hydraulic press and a pneumatic press depends on your manufacturing needs. Hydraulic presses are perfect for high-force, heavy-duty tasks, while pneumatic presses excel in speed and precision for lighter jobs.

For businesses seeking versatility, hydropneumatic presses combine the speed of pneumatic systems with the power of hydraulics. Companies like TSD offer customized hydraulic and pneumatic presses, ensuring reliability and efficiency tailored to your needs. Consider evaluating your requirements to choose the most suitable press and improve productivity while reducing operational costs.

A: A hydraulic press uses liquid pressure to generate force, while a pneumatic press relies on compressed air. Hydraulic presses offer higher force and precision, making them ideal for heavy-duty tasks.

A: Choose a hydraulic press for high-force applications, like deep drawing or molding, where precise, sustained pressure is needed.

A: Yes, hydraulic presses typically have higher initial and maintenance costs due to their complex components and power requirements.

A: Pneumatic presses are better suited for lighter tasks, as they provide lower force compared to hydraulic presses, which excel in heavy-duty operations.

A: Hydraulic presses offer greater force, precision, and control, making them suitable for tasks that require high pressure and accuracy.