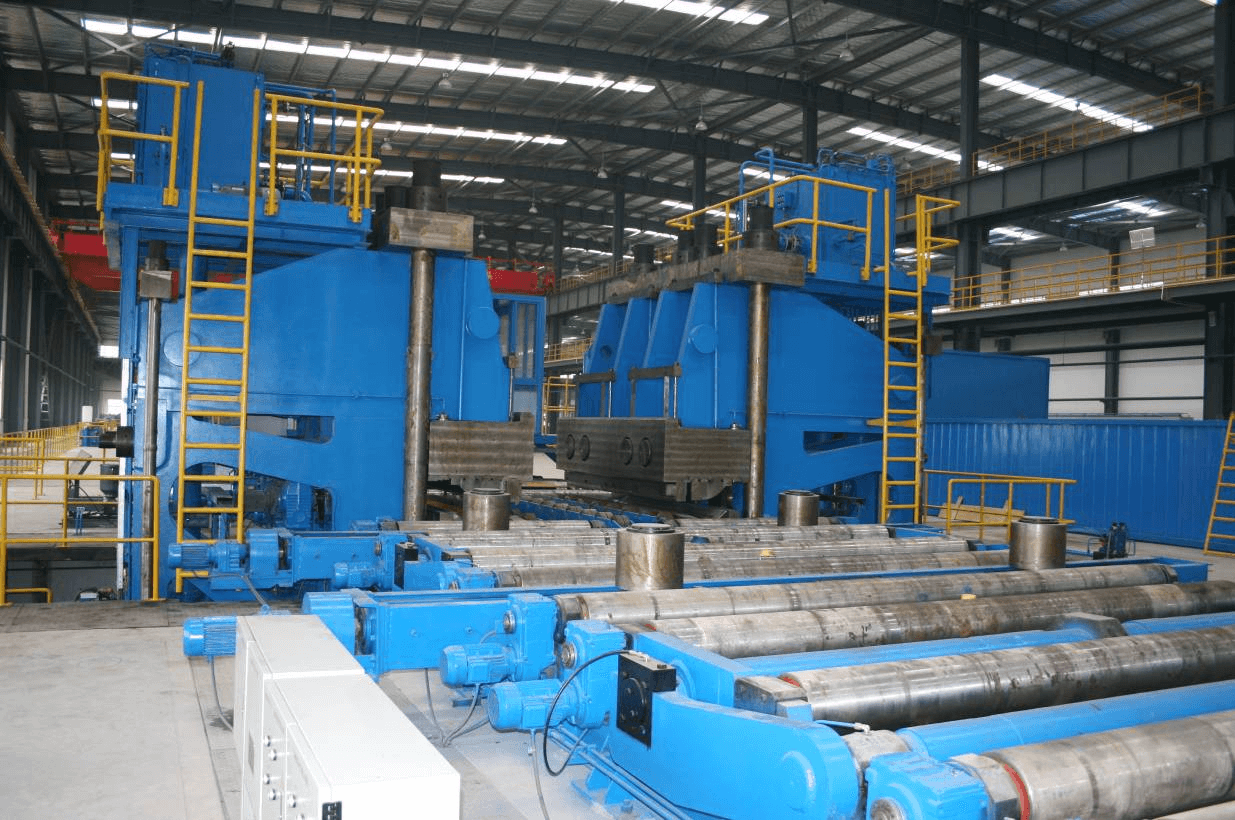

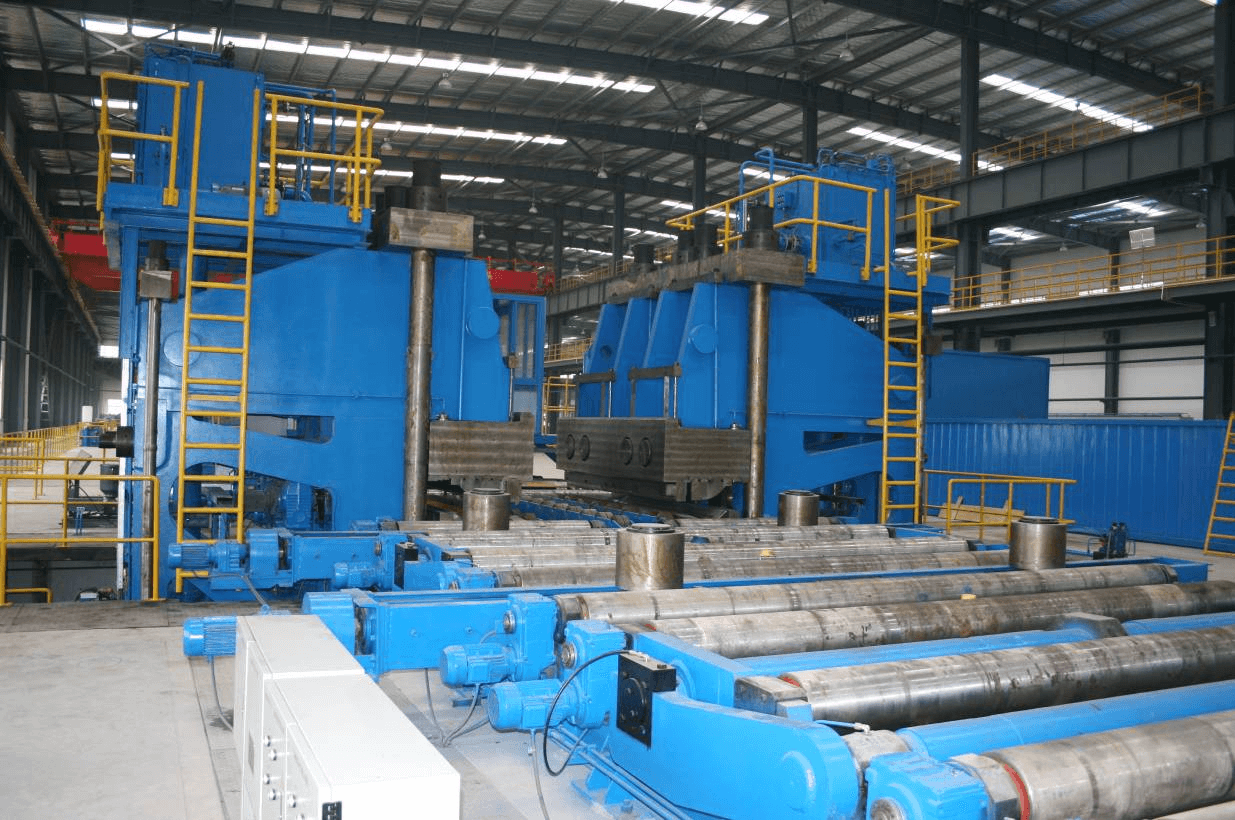

In the realm of industrial manufacturing, the Plate Pre Bending Machine plays a pivotal role in the production of steel pipes, particularly those used in the oil and gas industry. This specialized equipment is essential for ensuring the roundness and integrity of steel pipes by pre-bending the edges of steel plates before they are formed into pipes. For those interested in the intricacies of industrial machinery, understanding the function and importance of the Plate Pre Bending Machine is crucial.

The Role of Plate Pre Bending Machines in Manufacturing

Plate Pre Bending Machines are indispensable in the production line of Longitudinal Submerged Arc Welded (LSAW) pipes. Positioned between the milling machine and the forming machine, they are responsible for pre-bending the edges of steel plates that have been processed by the milling machine. This process is crucial for ensuring that the curvature radius of the forming pipe is maintained, thereby guaranteeing the roundness of the final product.

The machine operates by applying pressure to the edges of the steel plates, which have been beveled by the milling machine. This pre-bending process prevents the formation of excessively long straight edges in the final pipe, which can compromise its structural integrity and roundness. By ensuring that the edges of the steel plates are pre-bent to match the desired curvature radius, the Plate Pre Bending Machine plays a critical role in the quality control of steel pipe production.

Working Principle and Mechanism

The working principle of the Plate Pre Bending Machine involves the use of upper and lower dies to apply pressure to the steel plates. The plates are fed into the machine section by section, where they are positioned between the upper and lower dies. Under the pressure exerted by these dies, the material flows and bends, achieving the desired curvature. The relative position of the dies can be adjusted to ensure that the curvature radius of the plate edges closely matches that of the finished steel pipe.

This machine is designed to handle a wide range of plate thicknesses and lengths, making it versatile and adaptable to various production requirements. The use of CNC systems for step feeding and control enhances the precision and efficiency of the pre-bending process, allowing for consistent and high-quality results.

Technical Specifications and Features

The Plate Pre Bending Machine is equipped with advanced features that enhance its performance and reliability. It consists of a main machine and secondary equipment, including a frame, bed, cylinder unit, lower tool beam, clamping beam, and tool moving mechanism. The hydraulic system, lubrication system, and electrical system are integral components that ensure smooth and efficient operation.

The TSD Company BWQ-1500/3000 model is engineered with outstanding technical specifications to meet demanding production needs. It is capable of handling plate lengths from 8,000 mm to 12,200 mm and thicknesses ranging from 8 mm to 32 mm. With a production capacity of up to seven pieces per hour, the BWQ-1500/3000 delivers high efficiency and reliability. This exceptional productivity is achieved through the integration of advanced hydraulic and electrical systems, sourced exclusively from reputable global manufacturers, ensuring stable performance and long-term durability.

Applications and Industry Impact

The Plate Pre Bending Machine is primarily used in the production of steel pipes for the oil and gas industry. Its ability to pre-bend the edges of steel plates ensures that the final pipes have the required roundness and structural integrity, which are critical for their performance in demanding environments. By preventing the formation of straight edges, the machine enhances the overall quality and reliability of the pipes, reducing the risk of failures and leaks.

In addition to its applications in the oil and gas industry, the Plate Pre Bending Machine is also used in the production of steel pipes for other industries, such as construction and infrastructure. Its versatility and adaptability make it a valuable asset for manufacturers looking to produce high-quality steel pipes that meet stringent industry standards.

Conclusion

In conclusion, the Plate Pre Bending Machine is a vital component in the production of steel pipes, particularly for the oil and gas industry. Its ability to pre-bend the edges of steel plates ensures the roundness and structural integrity of the final pipes, which are essential for their performance in demanding environments. By understanding the role and importance of this machine, manufacturers can enhance the quality and reliability of their products, ultimately contributing to the success and sustainability of their operations. F

FAQs

1. What is the primary function of a Plate Pre Bending Machine?

The primary function of a Plate Pre Bending Machine is to pre-bend the edges of steel plates before they are formed into pipes, ensuring the roundness and structural integrity of the final product.

2. How does a Plate Pre Bending Machine work?

The machine works by using upper and lower dies to apply pressure to the steel plates, bending them to the desired curvature radius to match the final pipe's specifications.

3. What industries benefit from using Plate Pre Bending Machines?

Industries such as oil and gas, construction, and infrastructure benefit from using Plate Pre Bending Machines due to their ability to produce high-quality steel pipes.

4. What are the key technical specifications of a Plate Pre Bending Machine?

Key specifications include the ability to handle plate lengths from 8000 to 12200 mm, plate thicknesses from 8 to 32 mm, and a production capacity of up to seven pieces per hour.

5. Why is pre-bending important in pipe manufacturing?

Pre-bending is important because it prevents the formation of straight edges, ensuring the roundness and structural integrity of the final pipe, which is crucial for its performance.

6. How does the CNC system enhance the performance of a Plate Pre Bending Machine?

The CNC system enhances performance by providing precise control over the step feeding and bending process, ensuring consistent and high-quality results.

7. What are the main components of a Plate Pre Bending Machine?

Main components include the frame, bed, cylinder unit, lower tool beam, clamping beam, tool moving mechanism, hydraulic system, lubrication system, and electrical system.