content is empty!

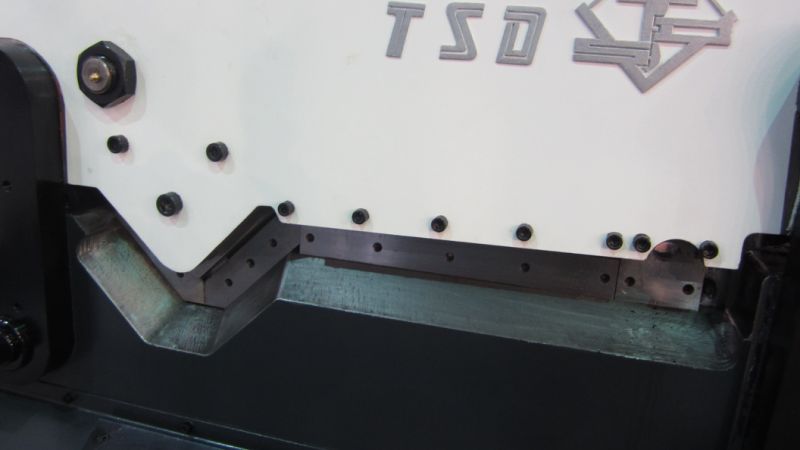

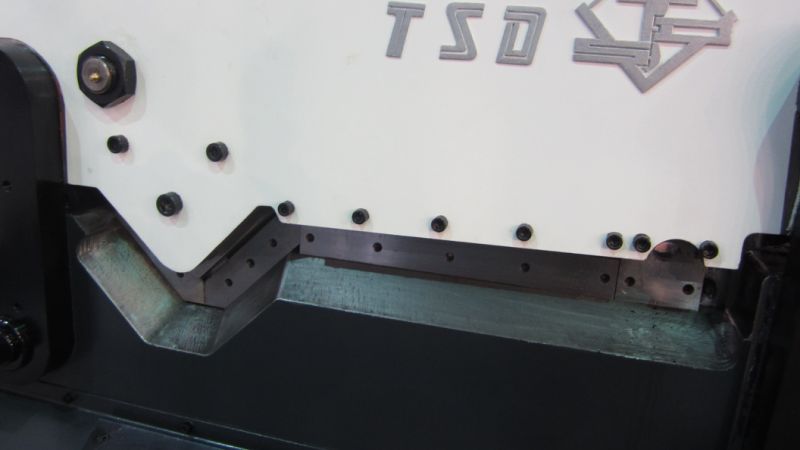

Q34Y-110

TSD

Combined punching and shearing machine

model Q34Y-110

Featurs:

- One ram structure driven by one oil cylinder

- Six standard working positions -Cutting manually or in foot pedestal

- Punching hole, positioning, pressing for sheet, Cutting round steel & square steel

- Cutting sheet, flat steel & angle steel. Slotting and Notching for sheet and angle steel

- Punching hole and positioning for angle steel

- With optional tool, cutting channel steel, Cutting round pipe & Bending tube are available

- Quick changing tools and Automatic holding plate

- Interlocking & protecting

- High manufacturing precision. Simple, high efficient & flexible operations

Combined punching and shearing machine

model Q34Y-110

Featurs:

- One ram structure driven by one oil cylinder

- Six standard working positions -Cutting manually or in foot pedestal

- Punching hole, positioning, pressing for sheet, Cutting round steel & square steel

- Cutting sheet, flat steel & angle steel. Slotting and Notching for sheet and angle steel

- Punching hole and positioning for angle steel

- With optional tool, cutting channel steel, Cutting round pipe & Bending tube are available

- Quick changing tools and Automatic holding plate

- Interlocking & protecting

- High manufacturing precision. Simple, high efficient & flexible operations

Main technical parameters

| Punching Position | Item | Value | Unit | Standard/Optional tools |

| Size of working table | 536*370 | mm | ||

| Max. pressing force | 1100 | KN | ||

| Max.cutting plate size (Thickness*width) | 25*300 20*450 12*500 | mm | Cutting 20*450mm sheet available with machine | |

| Not removing the blade for round(angle) steel, Max.cutting plate width is 400 mm | ||||

| Max.cutting angle steel | 160*160*16 | mm | Available with machine | |

| Max.punching hole force | 1100 | KN | ||

| Max.punching hole size | Ф38*25 | mm | Punching Ф12*16mm hole available with machine | |

| Cutting Round steel or Square steel | Round steel: Ф12~Ф50 | mm | CuttingФ12~Ф30mm round steel available with machine | |

| Square steel: 12~35 | Cutting square steel, the blade is optional; CuttingФ30~Ф50mm round steel, the lower blade is optional. | |||

| Cutting channel steel | 50~200 | mm | Option | |

| Sheet bending | 100*300 | mm | Option | |

| Notching Position | Size of working table (left-right*front-back) | 485*510 | mm | |

| Nominal force | 850 | KN | ||

| Max.notching size (width*depth*thickness) | 100*150*10 | mm | Available with machine | |

| motor power | 15 | kW | ||

| Overall dimensions (L*W*H) | 2300*1690*1087 | mm | ||

| Weight | 2800 | kg | ||

Packing :Coating with anti-rust oil on working surface, with plastic film layer for whole machine. Packed in container

Main technical parameters

| Punching Position | Item | Value | Unit | Standard/Optional tools |

| Size of working table | 536*370 | mm | ||

| Max. pressing force | 1100 | KN | ||

| Max.cutting plate size (Thickness*width) | 25*300 20*450 12*500 | mm | Cutting 20*450mm sheet available with machine | |

| Not removing the blade for round(angle) steel, Max.cutting plate width is 400 mm | ||||

| Max.cutting angle steel | 160*160*16 | mm | Available with machine | |

| Max.punching hole force | 1100 | KN | ||

| Max.punching hole size | Ф38*25 | mm | Punching Ф12*16mm hole available with machine | |

| Cutting Round steel or Square steel | Round steel: Ф12~Ф50 | mm | CuttingФ12~Ф30mm round steel available with machine | |

| Square steel: 12~35 | Cutting square steel, the blade is optional; CuttingФ30~Ф50mm round steel, the lower blade is optional. | |||

| Cutting channel steel | 50~200 | mm | Option | |

| Sheet bending | 100*300 | mm | Option | |

| Notching Position | Size of working table (left-right*front-back) | 485*510 | mm | |

| Nominal force | 850 | KN | ||

| Max.notching size (width*depth*thickness) | 100*150*10 | mm | Available with machine | |

| motor power | 15 | kW | ||

| Overall dimensions (L*W*H) | 2300*1690*1087 | mm | ||

| Weight | 2800 | kg | ||

Packing :Coating with anti-rust oil on working surface, with plastic film layer for whole machine. Packed in container

After-sale-service:

1. The Seller has passed ISO9001 quality system certification since 1997, and always execute strictly this quality

management system in our company and on our products.

All products before ex-works have been strictly tested and are in conformity with technical agreement and

standard.

2. Warranty is one year since the date of B/L, or final acceptance date of heavy duty machinery. Longer warranty

could be purchased by the user.

3. Commissioning: For heavy-duty machinery, the Seller sends technicians (electrical hydraulic & mechanical)

to guide the installation, testing and training the operators from 7 days to 45 days after the machine

reaches the factory of user. But the round-trip air tickets, local accommodation and allowance

(USD100/person·day) in the User's country will be burdened by the Buyer. The above charges do not be

included in the offer. This clauses will be shown in the contract.

3. For middle and small standard machinery, it is easy to operate according to operating manual. The User is

firstly suggested to carefully read operating manual, then start the machine. Any unclear issues, please feel

free to contact the Seller.

If the User insists on supplying the technical service at use's factory, please refer to No.2 clauses of after-sale-

service.

4. All products of the Seller can be tracked by Ex-works number. Spare parts can be supplied same as the former,

which is helpful for customers' special designing requirements.

5. Consumable parts can be supplied free of charge to customer within one year warranty from B/L date, and the

long term technical consultant service is available.

6. Common failure could be solved by E-mail, Phone and long distance video diagnose. The User must supply full

failure description, clear pictures and videos, if possible.

Once the serious quality problem is appeared due to the Seller's manufacturing reason within one year since

B/L date or final acceptance date of heavy duty machinery. The Seller will send their technician to repair it .

7. After one year warranty, the Seller will provide free technical consultation and spare parts and technician

service at lowest cost.

After-sale-service:

1. The Seller has passed ISO9001 quality system certification since 1997, and always execute strictly this quality

management system in our company and on our products.

All products before ex-works have been strictly tested and are in conformity with technical agreement and

standard.

2. Warranty is one year since the date of B/L, or final acceptance date of heavy duty machinery. Longer warranty

could be purchased by the user.

3. Commissioning: For heavy-duty machinery, the Seller sends technicians (electrical hydraulic & mechanical)

to guide the installation, testing and training the operators from 7 days to 45 days after the machine

reaches the factory of user. But the round-trip air tickets, local accommodation and allowance

(USD100/person·day) in the User's country will be burdened by the Buyer. The above charges do not be

included in the offer. This clauses will be shown in the contract.

3. For middle and small standard machinery, it is easy to operate according to operating manual. The User is

firstly suggested to carefully read operating manual, then start the machine. Any unclear issues, please feel

free to contact the Seller.

If the User insists on supplying the technical service at use's factory, please refer to No.2 clauses of after-sale-

service.

4. All products of the Seller can be tracked by Ex-works number. Spare parts can be supplied same as the former,

which is helpful for customers' special designing requirements.

5. Consumable parts can be supplied free of charge to customer within one year warranty from B/L date, and the

long term technical consultant service is available.

6. Common failure could be solved by E-mail, Phone and long distance video diagnose. The User must supply full

failure description, clear pictures and videos, if possible.

Once the serious quality problem is appeared due to the Seller's manufacturing reason within one year since

B/L date or final acceptance date of heavy duty machinery. The Seller will send their technician to repair it .

7. After one year warranty, the Seller will provide free technical consultation and spare parts and technician

service at lowest cost.