A plate rolling machine is a fundamental piece of equipment in the metal fabrication industry, enabling manufacturers to transform flat metal sheets into cylindrical, conical, or arc-shaped forms. This capability is essential for industries such as construction, aerospace, shipbuilding, and pressure vessel manufacturing. With the right understanding of the machine's functionality, types, and applications, businesses can optimize production processes and ensure precise, high-quality results.

What Is a Plate Rolling Machine?

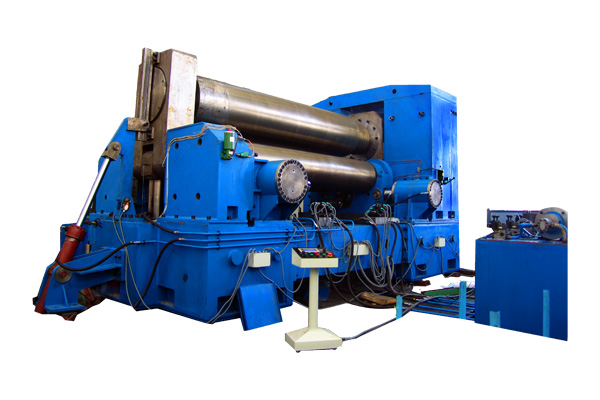

A plate rolling machine, also known as a plate bending machine or roll bending machine, is a mechanical device used to bend flat metal plates into specific, often complex shapes. The machine uses a set of rollers to apply controlled pressure on the metal sheet, gradually forming the material into the desired curvature. Depending on the design of the machine, the rollers can bend the plate into cylindrical, conical, or other multi-radius shapes. The process involves plastic deformation, where the metal retains the new shape once the bending force is removed.

Key Features of Plate Rolling Machines:

Roller Configuration: Most machines use a set of three or four rollers to apply pressure. Some modern systems use advanced technology to allow for even more precise control of the roller positions and pressure.

Adjustability: Many machines offer adjustable settings for different material thicknesses and bending radii. This enhances their versatility, making them ideal for a range of applications.

Automation: High-end models may come equipped with CNC (Computer Numerical Control) systems that offer greater accuracy and reduce manual intervention, increasing overall production efficiency.

Types of Plate Rolling Machines

Plate rolling machines come in various designs, each tailored for specific types of work. The following are the most common types of plate rolling machines:

1. Three-Roll Plate Rolling Machines

These machines feature three rollers: one top roll and two bottom rolls. The top roll applies pressure to the metal sheet, while the bottom rolls support and guide the material. Three-roll machines are commonly used for lighter to medium-duty applications, such as producing cylindrical and arc-shaped components. They are particularly useful for manufacturing pipes, barrels, and other structures that require consistent, simple curvature.

Advantages:

Cost-Effective: Ideal for smaller projects due to its relatively lower price.

Simple Operation: Easy to use for straightforward tasks, requiring less technical expertise.

Limitations:

Limited Precision: While functional for many applications, the precision level is lower compared to more advanced systems.

Pre-Bending Challenges: The three-roll system is less efficient in pre-bending plate edges, which may result in slight distortions.

2. Four-Roll Plate Rolling Machines

A four-roll plate rolling machine features an additional bottom roll, which gives it greater control and precision during the bending process. The extra roll allows for better pre-bending of plate edges, ensuring a more uniform cylindrical form. Four-roll machines are ideal for more complex, heavy-duty applications that require bending thicker materials.

Advantages:

Higher Precision: The extra bottom roll improves the consistency of bends.

Thicker Materials: Can handle thicker plates and achieve more precise results for complex shapes.

Enhanced Pre-Bending: The ability to pre-bend the plate edges makes it easier to achieve the perfect cylindrical shape.

Limitations:

Higher Cost: Four-roll machines are typically more expensive than their three-roll counterparts.

Increased Complexity: They require more skill to operate effectively, making them less suited for simpler tasks.

3. Variable Geometry Plate Rolling Machines

These machines are designed with adjustable configurations that allow for flexible bending of plates with varying thicknesses and radii. The ability to modify the geometry of the rolls gives these machines a high degree of versatility, enabling them to produce a wide range of shapes and sizes.

Advantages:

Extremely Versatile: Able to produce a wide range of shapes, from simple cylinders to more intricate forms.

Precision Control: Offers the ability to adjust settings to suit different material thicknesses and bending radii.

Higher Efficiency: The advanced design and adjustability allow for faster, more efficient production of customized parts.

Limitations:

Cost: Variable geometry machines are among the most expensive types available.

Complexity: They require highly trained operators to fully utilize their advanced features.

Working Principle of Plate Rolling Machines

The operation of a plate rolling machine follows a series of well-defined steps that involve a combination of mechanical and hydraulic systems to achieve the desired bending:

Loading: The flat metal sheet is placed between the rollers.

Pre-Bending: The initial bending of the plate edges is performed to remove flat spots and prepare the edges for further bending.

Rolling: The top roll applies pressure, while the bottom rolls guide and rotate the material, gradually curving it into a cylindrical or conical shape.

Correction: Post-bending adjustments are made to ensure uniform curvature and eliminate any distortions.

During the process, the metal undergoes plastic deformation, allowing it to retain its new shape after the bending force is removed.

Applications of Plate Rolling Machines

Plate rolling machines are widely used in industries where curved metal components are essential. These industries require accurate and efficient bending of plates for various applications:

1. Construction

In the construction industry, plate rolling machines are used to create cylindrical components such as pipes, tanks, and structural supports. These components are essential for building infrastructure like bridges, tunnels, and skyscrapers. The ability to form large, precise metal structures is vital in maintaining the integrity and safety of construction projects.

2. Shipbuilding

Shipbuilders rely on plate rolling machines to fabricate the hulls and other curved sections of ships. The ability to produce large, curved metal plates is crucial for constructing seaworthy vessels, ensuring they are both durable and efficient. Plate rolling machines are also used to create curved components for submarines and other maritime structures.

3. Aerospace

In aerospace manufacturing, plate rolling machines are used to create lightweight, curved panels and components that must adhere to stringent safety and performance standards. These machines help produce parts for aircraft fuselages, wings, and other key structural elements that need to withstand extreme conditions and ensure passenger safety.

4. Pressure Vessel Manufacturing

Pressure vessels, such as boilers and reactors, require high-strength cylindrical bodies capable of withstanding internal pressure. Plate rolling machines are used to form the curved sections of these pressure vessels, ensuring they meet the required structural integrity and safety standards for high-pressure environments.

5. Automotive

In the automotive industry, plate rolling machines are used to create curved body panels, structural elements, and other parts that are crucial for the vehicle’s aerodynamics, safety, and performance. These machines help in producing complex shapes that contribute to the overall design and function of modern vehicles.

Advantages of Using Plate Rolling Machines

There are several significant advantages to using plate rolling machines in manufacturing processes, which contribute to increased efficiency and cost savings:

Precision: Modern machines offer high accuracy and consistent results, ensuring uniform bends and minimal distortion.

Versatility: The adjustable settings on many machines allow them to handle different materials and thicknesses, producing a variety of shapes.

Efficiency: Automated features and CNC controls streamline the process, reducing manual labor and increasing production speed.

Cost-Effectiveness: Bringing the rolling process in-house reduces the need to outsource, which can lower production costs and lead times.

Customization: The flexibility of plate rolling machines makes them ideal for custom fabrication, providing manufacturers with the ability to meet specific design requirements.

Conclusion

Plate rolling machines are indispensable tools in the modern manufacturing world, providing the ability to transform flat metal sheets into complex shapes that are essential for a wide range of industries. By understanding the various types of machines, their working principles, and the specific applications they serve, businesses can make informed decisions on the equipment that best suits their needs. With the right plate rolling machine, companies can achieve greater precision, efficiency, and cost-effectiveness in their production processes, resulting in high-quality metal components that meet industry standards.